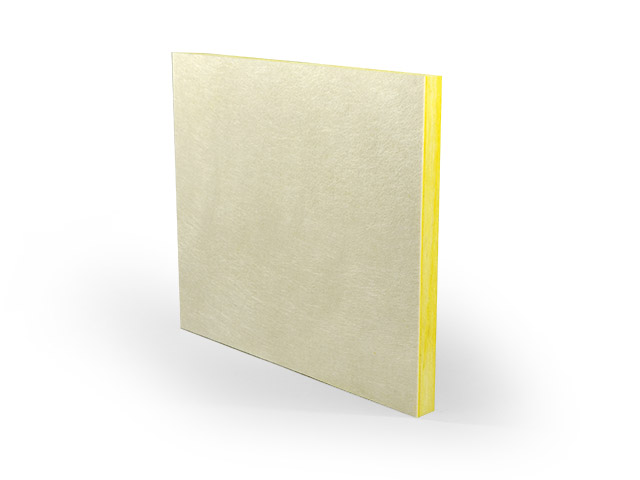

Green Glue is a visco-elastic soundproofing compound that, when sandwiched between two layers of a rigid material, greatly reduces the amount of sound transmission through walls or ceilings and reduces the amount of noise generated from impacts on floors. Available in 28 ounces tubes or 5-gallon pails.

Green Glue Noise proofing Compound for acoustics is a unique technology that can benefit both new construction and renovation projects. It is uniquely formulated to dissipate the vibrations caused by sound waves as they travel through ceilings, walls, and floors.

By dampening vibrations, Green Glue can reduce the amount of noise transferring from one side of the structure to the other. Green Glue works so well because it will always remain in a tacky state. Green Glue Noise proofing compound will never dry out and become rigid.

Green Glue Noise proofing Compound is fast and easy to apply. Just cut the tip, attach the nozzle, and Green Glue is ready to dispense using any standard quart-size caulk gun such as the Green Glue Tube Applicator. Apply Green Glue beads evenly over the entire back of the first layer of gypsum or sub flooring. Leave 3 inches on edge for handling. Install the second layer of gypsum or sub-flooring within 15 minutes, using proper screws and screw spacing.

FEATURES:

- Applies in just minutes

- Improves sound transmission loss

- Helps block sound

- Superb low frequency attenuation

- Easy to apply

- Non-toxic

For applying Green Glue, we recommend purchasing the Green Glue Applicator Gun. This caulking gun is designed specifically for easy and precise application of Green Glue.

* * * Green Glue is not a fastening glue; it will not hold the two boards together, so additional fastening is required to keep boards in place. * * *

Pemko 4131CRL Automatic Door Bottom, Surface Mounted, Clear Anodized Aluminum

1 × $74.99

Pemko 4131CRL Automatic Door Bottom, Surface Mounted, Clear Anodized Aluminum

1 × $74.99  Polyester Acoustic Columns (Grey) 6pk

1 × $295.00

Polyester Acoustic Columns (Grey) 6pk

1 × $295.00  Pemko 221AV36 Door Shoes Aluminum U Shape 3" Door Shoe/Kickplate, Vinyl Bottom Seal, 1-3/4" Door, 36"

1 × $59.00

Pemko 221AV36 Door Shoes Aluminum U Shape 3" Door Shoe/Kickplate, Vinyl Bottom Seal, 1-3/4" Door, 36"

1 × $59.00  SilentWrap™ Mass Loaded Vinyl PSA

1 × $335.00

SilentWrap™ Mass Loaded Vinyl PSA

1 × $335.00  Green Glue Whisper Clips

1 × $123.00

Green Glue Whisper Clips

1 × $123.00